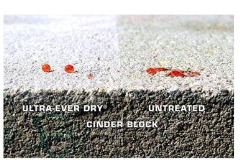

Ultra Hydrophobische Schicht -> extrem wasserabweisendes Material mit dem sogenannten Lotus Effect.

das Material ist bestellt und wird hoffentlich noch dieses Jahr getestet

->wir testen in den Osterferien auf dem Pitztal Gletscher

Ein Argument des Verkäufers war : im Video wirbt der Hersteller auch mit Zement auf einer Rutsche. Also muss das Material auch beständig gegen Reibung sein.

Fazit: wir werden es einfach testen. dann wissen wir das , was viele Snowboarder an fragen offen bleiben

ULTRA TECH 4000 ULTRA-EVER DRY BOTTOM COAT (GRUNDSCHICHT),1 QUART

http://shop.lager-betrieb.de/epages/280809

|

|

|

UltraTech 4000 Ultra-Ever Dry Bottom Coat, 1 quart, works with the Ultra-Ever Dry Top Coat (sold separately) to form the two-part Ultra-Ever Dry coating which helps repel water and oil from coated surfaces, protecting against corrosion caused by moisture and keeping coated surfaces dry, clean, and free of ice. The bottom coat adheres to many surfaces, creating a base layer to which the Ultra-Ever Dry top coat bonds. This product must be applied with Ultra-Ever Dry Top Coat (sold separately) and according to the instructions to be effective. The two-part coating adds a translucent white color and matte finish to coated surfaces after curing. The Ultra-Ever Dry Bottom Coat uses a solvent called xylene to allow the active ingredients to be sprayed on for a thin, uniform coating. The bottom coat adheres to steel, aluminum, and other metals, as well as plastic, leather, fabric, wood, concrete, and many other materials. The two-part coating is non-flammable after application and suitable for indoor and outdoor use.

The two-part coating is classified as a superhydrophobic coating as it exceeds 150 degrees of contact angle when measuring the sphere of a drop of water on the surface; this means that water, upon contacting the coated surface, forms very round beads which roll off quickly, without leaving the surface moist. It remains superhydrophobic for 30 cycles in a Taber abrasion tester with a CS-10 abrasive wheel. The two-part coating is also oleophobic, which means that it repels refined oil and many other hydrocarbons.

During the application and cleanup of Ultra-Ever Dry coatings, the use of a National Institute for Occupational Safety and Health (NIOSH)-approved P100 half-face respirator with an organic vapor cartridge, safety glasses, and protective gloves is recommended. The two-part coatings durability varies depending on exposure to abrasion, UV rays, and other outdoors conditions; recoating with the top coat will help extend Ultra-Ever Drys longevity.

Specifications for Ultra-Ever Dry two-part coating (Top Coat sold separately)

Viscosity (measured with a #3 Zahn cup)

|

8 seconds

|

Percent of solids

|

>10%

|

Surface application temperature

|

50 to 90 degrees F

|

Storage temperature

|

-40 to 115 degrees F

|

Shelf life

|

1 year at 77 degrees F

|

Coverage per gallon

|

240 sq. ft./22. sq. m

|

Working temperature

|

-30 to 300 degrees F

|

Bitte beachten:

- Verbrauchsmaterial/Flüssigkeiten -Lieferung nur gegen Vorauskasse!

- Mit der Auslieferung erhalten SieSicherheitsdatenblätterundtechnische Datenblätterin deutscher Sprache!

innerhalb 3 Tagen lieferbar

182,50 € / Dose(n)

Lieferung: FREI HAUS, zzgl. 19 % MwST.

|

Die eigentliche Deckschicht kostet über 300 Euro pro Liter

UltraTech 4001 Ultra-Ever Dry Top Coat, 1 quart, works with the Ultra-Ever Dry Bottom Coat (sold separately) to form the two-part Ultra-Ever Dry coating which helps repel water and oil from a coated surface, protecting against corrosion caused by moisture and keeping coated surfaces dry, clean, and free of ice. The top coat forms a thin coating that fills its own interstitial spaces with trapped air molecules to prevent water and oil from wetting the coated surface. This product must be applied over Ultra-Ever Dry Bottom Coat (sold separately) and according to the instructions to be effective. The two-part coating adds a translucent white color and matte finish to coated surfaces after curing. The Ultra-Ever Dry Top Coat uses a solvent called acetone to allow the active ingredients to be sprayed on for a thin, uniform coating. The top coat can help protect steel, aluminum, and other metals, as well as plastic, leather, fabric, wood, concrete, and many other materials. The two-part coating is non-flammable after application and suitable for indoor and outdoor use.

The two-part coating is classified as a superhydrophobic coating, as it exceeds 150 degrees of contact angle when measuring the sphere of a drop of water on the surface; this means that water, upon contacting the coated surface, forms very round beads which roll off quickly, without leaving the surface moist. It remains superhydrophobic for 30 cycles in a Taber abrasion tester with a CS-10 abrasive wheel. The two-part coating is also oleophobic, which means that it repels refined oil and many other hydrocarbons.

During the application and cleanup of Ultra-Ever Dry coatings, the use of a National Institute for Occupational Safety and Health (NIOSH)-approved P100 half-face respirator with an organic vapor cartridge, safety glasses, and protective gloves is recommended. The two-part coatings durability varies depending on exposure to abrasion, UV rays, and other outdoors conditions; recoating with the top coat will help extend Ultra-Ever Drys longevity.

Specifications for Ultra-Ever Dry two-part coating (Bottom Coat sold separately)

Viscosity (measured with a #3 Zahn cup)

|

8 seconds

|

Percent of solids

|

>10%

|

Surface application temperature

|

50 to 90 degrees F

|

Storage temperature

|

-40 to 115 degrees F

|

Shelf life

|

1 year at 77 degrees F

|

Coverage per gallon

|

240 sq. ft./22. sq. m

|

Working temperature

|

-30 to 300 degrees F

|

Bitte beachten:

- Verbrauchsmaterial/Flüssigkeiten -Lieferung nur gegen Vorauskasse!

- Mit der Auslieferung erhalten SieSicherheitsdatenblätterundtechnische Datenblätterin deutscher Sprache!

innerhalb 3 Tagen lieferbar

306,50 € / Dose(n)

Lieferung: FREI HAUS, zzgl. 19 % MwST.

Formularbeginn

In den Warenkorb

Formularende

|

|

|

|